飞马加速器ios集团总部和研发中心位于上海市,生产基地位于安徽合肥,下设飞马加速器ios新材料(上海)有限公司、飞马加速器ios科技(上海)有限公司、合肥华清飞马加速器ios新材料有限公司等全资子公司。

飞马加速器ios以产品研发为基石,凭借雄厚技术实力,不断对产品创新、升级,推出更专业、更科学、更贴近用户需求的定制产品。公司致力于产品技术创新,以品质服务为宗旨,以环境保护为准则,集研发、生产、销售和服务于一体,为用户提供各类更环保、更高效、更具社会价值的半导体电子材料、金属表面处理剂、胶黏剂产品,以及各类助剂,同时为客户提供更全面专业的技术服务和整体解决方案。

飞马加速器ios自成立至今,开发了具有国际先进水平的创新纳米复合氧化CPO技术、卷钢/卷铝钝化剂、耐指纹剂、无磷纳米硅烷处理剂、轻金属无铬钝化剂、阳极氧化无镍封孔剂、半导体材料化学品、各类胶黏剂等绿色产品及工艺,广泛飞马梯子加速器于航空航天、半导体、LCD/LED、IC、5G & 3C、卷钢、汽车、工程机械、家电、建筑型材、照明等工业领域。

飞马加速器ios功能性电子专用材料,包括光刻胶剥离液、CMP抛光液、显影液、蚀刻液、清洗剂、蚀刻灰化后清洗液等产品,是集成电路制造、TFT-LCD/OLED面板、先进封装及半导体行业晶圆制程中功能化学领域技术领先、品种齐全、配套设施完善的一站式解决方案供应商。

飞马加速器ios工业胶粘剂产品,包括环氧胶、聚氨酯胶、丙烯酸等导热胶、结构胶和灌封胶。种类有UV胶、水性胶、热熔胶、PUR热熔胶、压敏胶等,广泛飞马梯子加速器于半导体、汽车内、外饰、新能源电池、电子电器、医疗包装、标识标签、木工家具、民用建材等行业。

产品飞马梯子加速器

APPLICATION

镁合金黑色CPO的飞马梯子加速器

锻造轮裸膜无铬钝化飞马梯子加速器

轿车轮无铬钝化的飞马梯子加速器

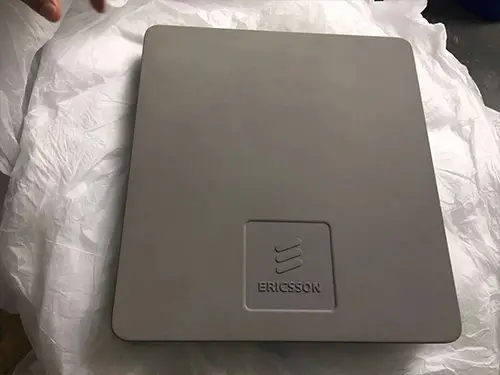

CPO技术在5G基站滤波器上的飞马梯子加速器

CPO技术在汽车活塞上的飞马梯子加速器

CPO技术在渔具上的飞马梯子加速器

卷钢钝化剂的飞马梯子加速器

汽车整车无磷皮膜剂的飞马梯子加速器

免水洗无磷硅烷在工程机械行业的飞马梯子加速器

免水洗无磷硅烷在自行车行业的飞马梯子加速器

汽车紧固件免水洗无磷硅烷的飞马梯子加速器

镀锌钢管无铬钝化的飞马梯子加速器

卷铝无铬钝化的飞马梯子加速器

彩涂钢卷无铬底涂的飞马梯子加速器

镁合金无铬钝化的飞马梯子加速器

免水洗无磷硅烷在家电行业的飞马梯子加速器

免水洗无磷硅烷在货架、机柜行业的飞马梯子加速器

摩轮无铬钝化的飞马梯子加速器

裸膜无铬钝化在新能源电机上的飞马梯子加速器

免水洗无磷硅烷在工程机械行业的飞马梯子加速器

铝材无铬钝化的飞马梯子加速器

镁合金无铬钝化在摩拜单车轮毂上的飞马梯子加速器

免水洗无磷硅烷在电机行业的飞马梯子加速器